Compression moulding technology

■ What is it?

Aisa’s compression moulding technology at the forefront

- Extruder with axial pressure piston for better material melts and fast colour change.

- Optimised extruder and dosing heating profile for evenly low-tempered doses and improved sleeve welding.

- Spiral flow dosing head for stress-free symmetrical doses.

- Volumetric dosing eliminates dose weight variation.

- High-cooling moulds available designed and produced in-house with laser sintering.

- Adaptive two-step compression process, enabling compression mode choice according to material and design criteria.

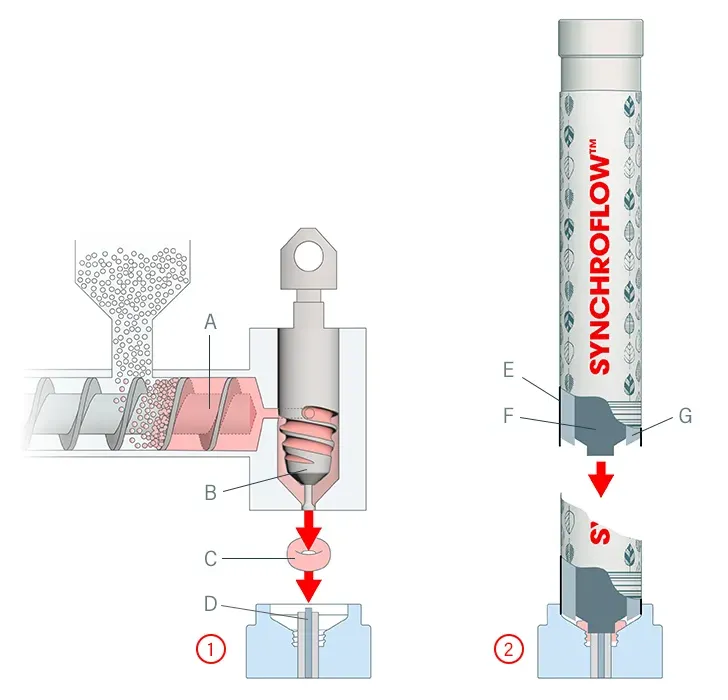

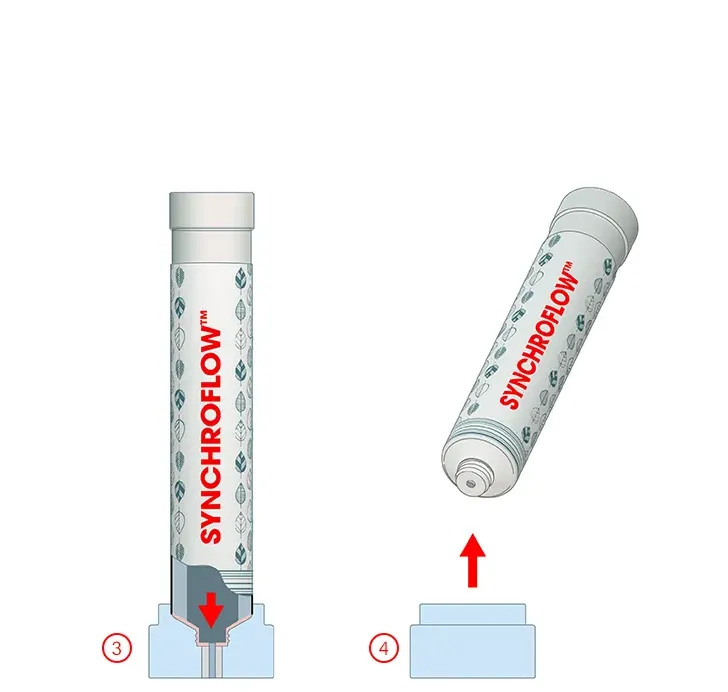

1. Volumetric dosing (B) eliminates dose weight variation of the doughnut (C).

2. Outer and inner parts (F)(G) of the mandrel are pushed down.

The outer part (G) of the mandrel is closing the mould before pressure is applied.

The outer part (G) of the mandrel is closing the mould before pressure is applied.

3. Inner part (F) of the mandrel is pushed further down to form the mould for the tube head.

4. The mandrel lifts up; the shoulder is perfectly moulded and welded with a clean orifice to the sleeve.

A. Extruder with axial pressure piston

B. Volumetric dosing system

C. Doughnut (PE dose)

D. Orifice pin

E. Sleeve

F. Internal mandrel

G. External mandrel

■ Synchroflow™ technology benefits

- Enhanced tube shoulder appearance.

- Excellent aesthetics, no flow lines on coloured shoulder.

- Perfect welding for round shoulders.

- Cleaner and smaller orifice now possible.

- No air trapped on the shoulder head.

- No crooked shoulder head.

- Improved economics.

- Faster and less frequent tooling change-over.

- Improved process stability leading to higher productivity.

- Reduced tooling needs, through standardisation.

- Up to 60% lower investment on dosing nozzles.

- Faster colour change-over.

Our other technologies :

Do you have a question?

Contact us now for more information!