Simply a perfect seam

■ What is it?

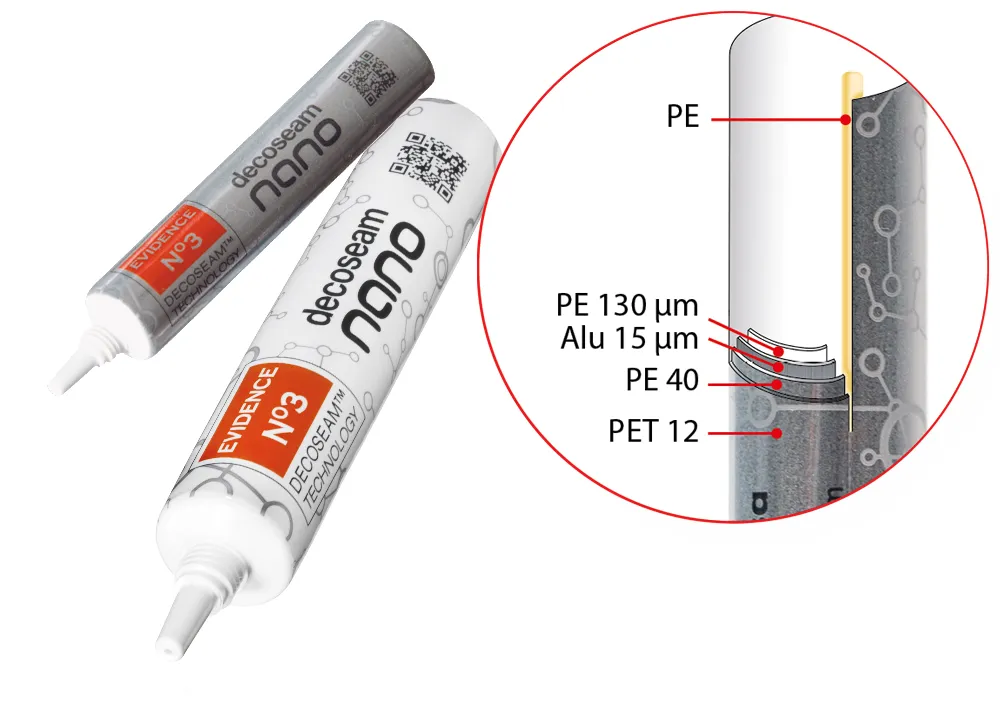

The Decoseam™ Nano has a simple, yet clean production process. It can be implemented on Hiflex machines and complements the standard Decoseam™ technology by covering the smaller diameter range of 30 mm down to 10 mm. It is the edge-welding technology of the Decoseam™ Nano that sets it apart.

■ Available on

SAESA®100, SAESA®200, BM 120 and BM 240 lines running at outputs of 100, 200, 120 and 240 tubes or sleeves/min.

■ Advantages

- Extremely good protection of the side-seam foil edges.

- No moving parts in the welding shaft, reducing contamination risk ideally suited for pharmaceutical packaging.

- Only few welding parameters, for less production variation.

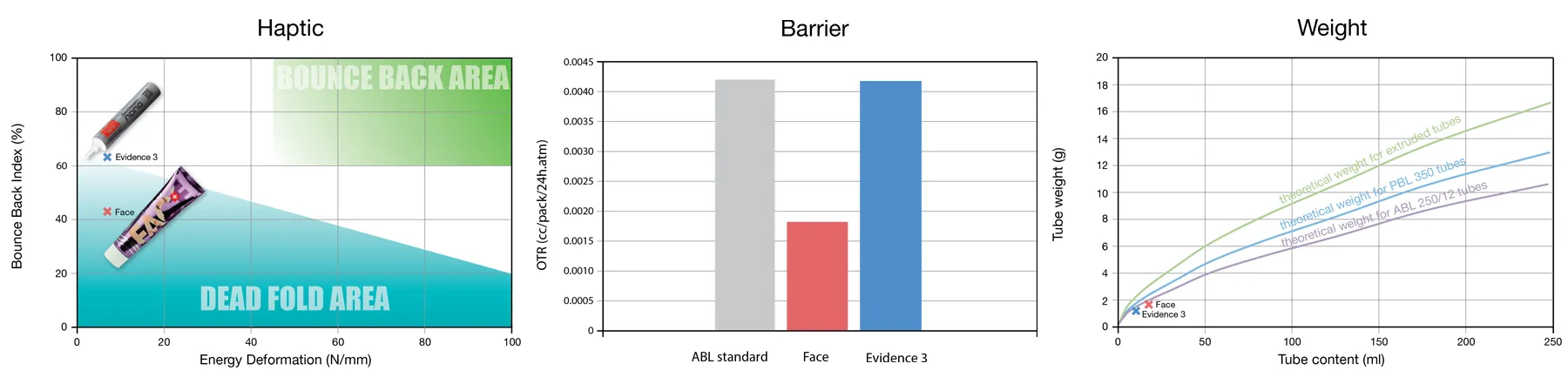

Face

■ Packaging technology

- Digitally CMYK inkjet-printed, creating effects using the metallic surface of the substrate.

- Laminate sleeve high gloss structure; 300 µm thick, metallised PET surface and 9 µm aluminium barrier layer.

- Edge-welded, fully decorated side-seam with reinforcement strip PE/PET/PE on the inside.

- Aluminium layer for product protection. Thin inner PE layer for reduced scalping.

- Heading using pre-moulded PE shoulder, high-frequency welded to the tube sleeve.

- Cylindrical screw cap.

- Identical barrier properties as standard ABL tube (BIF 1).

- Bounce back index: 31%.

Evidence 3

■ Packaging technology

- Digitally CMYK inkjet printed.

- ~ Eighty percent bio-sourced tube made of laminate PEbio70/PAP150g/PETHB12/PEbio70.

- Bio-sourced PE shoulder.

- Paper contributes to the unique touch.

- PET HB adds mechanical strength and barrier properties.

- Identical barrier properties to standard PBL tube (BIF 1).

- Bounce-back index: 78%.

Our other technologies :

Do you have a question?

Contact us now for more information!