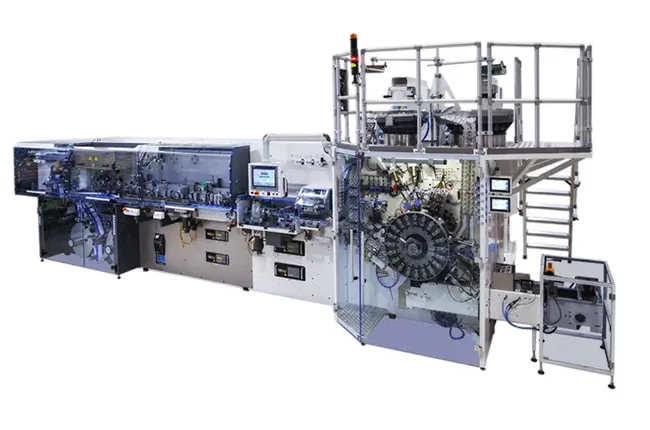

Most flexible fully automatic hiflex-line dedicated to the production of ABL or PBL laminate tubes at speeds of up to 200 tubes per minute, with traditional overlap or edge-welded side-seam.

Hotline : +41 840 84 84 84

■ Key benefits

- Decoseam™ 360° decoration

- Simple, highly efficient tooling

- Technology for the tube markets of today and tomorrow

- Integrated electrical cabinet

- Quick change-over

- Small foot print

- Low maintenance

- Same operational method as BM on SAESA® models

Technologies: :

-

SAESA®

-

Decoseam™

-

Decoseam™ Nano

-

Smart Cap

(Click on the icons for more information)

Machine specifications

Machine capabilities

Up to 200 tubes/min.

Tube Ø12.7 mm to 50 mm

Side-seam up to 40m/min.

Welding technologies

DIBS – Double Induction Belt Sealing for both aluminium and plastic barrier laminate (ABL and PBL)

Value-adding options

Circumferential cutter

AFQS – Automatic Functional Quality System

Decoseam™ edge-welding

Decolap, overlap side-seam

Safety seal applicator

Snap-on cap applicator with print orientation

Packing machine connection

Production Data Interface to MES

QUALITY CONTROL SYSTEMS

iQ-Seam Compression

Q-Seam Aesthetic

Vision-based quality control systems