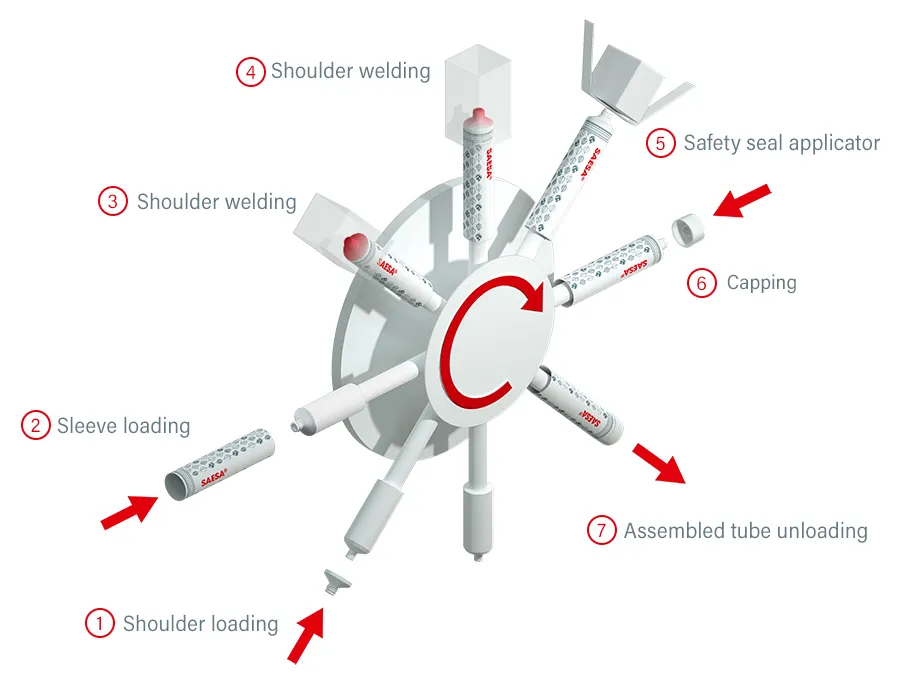

Component assembly technology

■ What is it?

Saesa® tube packaging assembly technology is a process that assembles sleeves, moulded shoulders and caps together into finished tubes, ready to be filled.

■ Advantages

- Scalability – by simply multiplying the assembly stations, machines run from 100 to 600 tubes per minute, with compact footprints.

- High performance – processing is times are not slowed down by cooling time required in a component moulding process.

- Shoulder and cap are assembled on the same mandrel.

- High flexibility – add additional value capabilities such as cap or shoulder orientation, oval tube capability with or without safety seal applicator.

- Cold shoulder allows for a more stable capping process, eliminating the risk of shrinkage inherent in in-line moulding operation.

■ Available on

SAESA®100, SAESA®120, SAESA®200, SAESA®240 and SAESA®600 lines running at outputs of 100, 120, 200, 240 and 600 tubes/min.

■ Markets

- To our knowledge, more than 33 billion laminate tubes are sold yearly; we estimate that more than half or these are produced by Aisa machines, based on global installed machine capacity.

- The largest market segment for laminate tubes is toothpaste production, but this is far from their only use. From 12.7 mm diameter paint tubes for artists, to 19 mm pharmaceutical eye ointments, all the way to 40 mm sweet condensed milk and 50 mm cosmetic hair-treatment shampoos, Saesa® tubes have countless applications today.

Our other technologies :

Do you have a question?

Contact us now for more information!