Tube labelling, Aisa-Style

■ What is it?

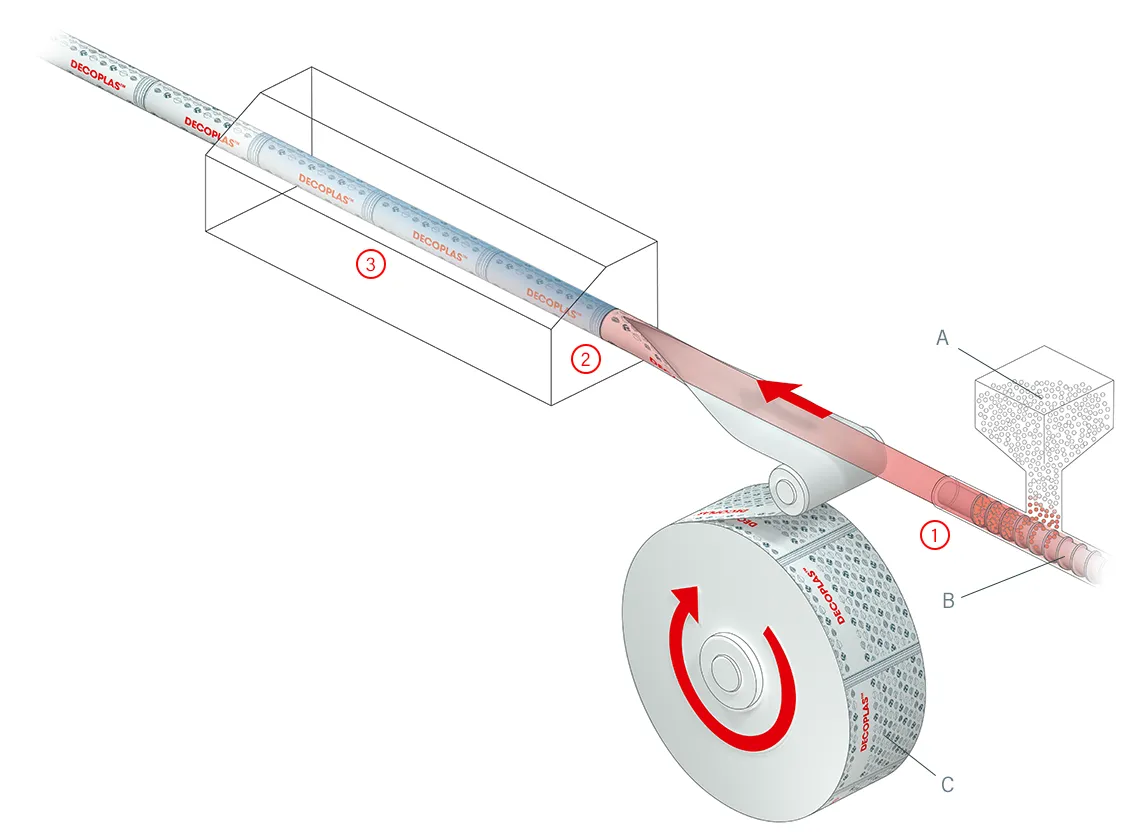

Decoplas™ is a revolutionary technology developed by Aisa which combines standard plastic tube extrusion with innovative labelling decoration. Decoplas™ tube has unmatched bounce-back properties and 360° decoration using a printed film.

1. Extruded tube

2. Laminate wrapped and welded by heat arround the tube

3. Tube calibrated and cooled

A. Raw material for extrusion

B. Extruder with axial pressure piston

C. Decorated laminate

■ Markets

-

Packaging users who want the decorative and logistical advantages of the label in a tube format but with the feel and touch of an extruded tube.

■ Available on

DXL 120 machine running at outputs of 120 sleeves/min.

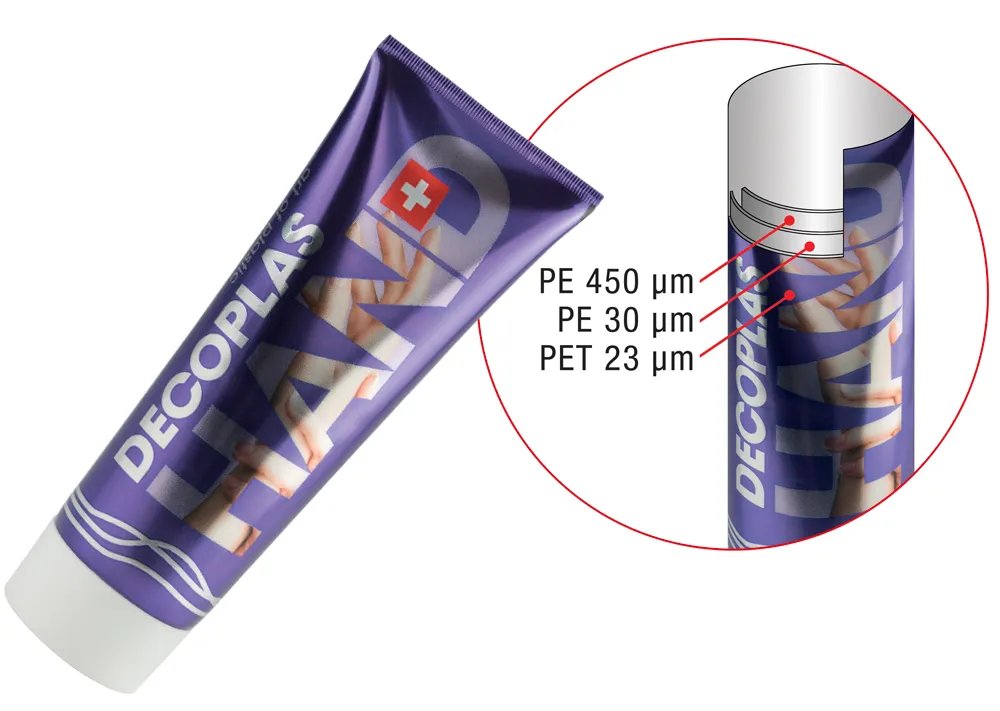

Hand

■ Packaging technology

- Digitally printed, metallised PET/PE film.

- Extruded monolayer PE tube sleeve with PET barrier added through film.

- Heading using pre-moulded PE shoulder, heat-sealed to the tube sleeve.

- Cylindrical screw-on cap.

- Improved barrier properties vs standard PE tube (BIF 9.5).

- Bounce-back index: 80%.

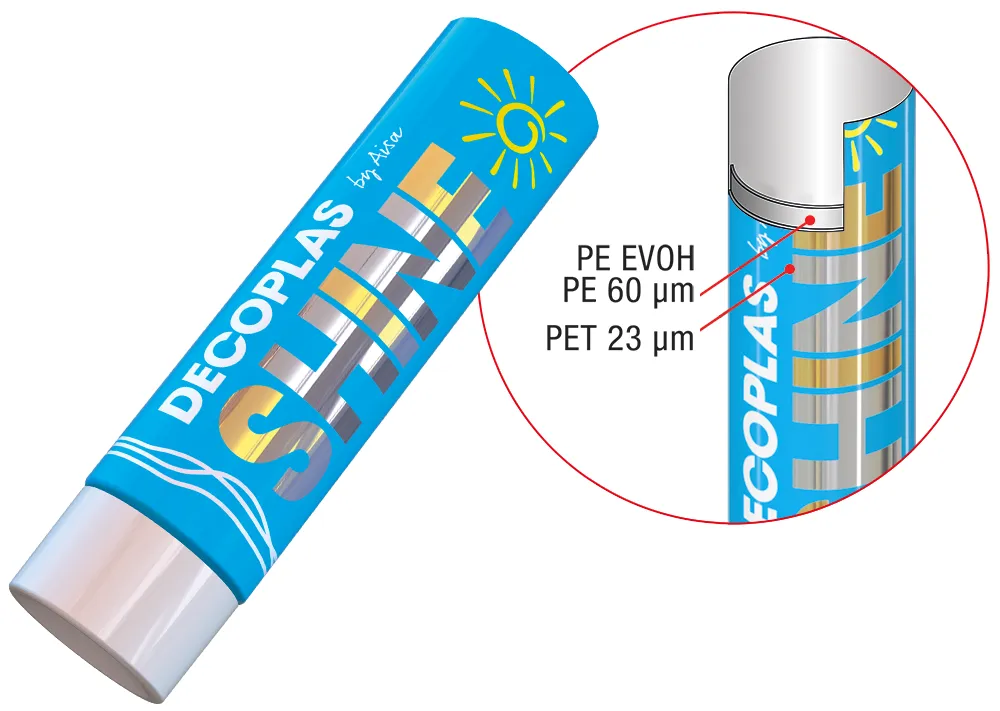

Shine

■ Packaging technology

- Eighty micrometres PET/PE evoh PE film.

- Digital hybrid decoration can combine inkjet, flexography UV, cold foil and silk screen printing efficiently in-line.

- Extruded monolayer PE tube sleeve with barrier added through film.

- Cylindrical screw-on cap.

- Identical barrier properties to co-extruded or PBL tube.

- Bounce back index: 80%.

C-PACK Decoplas™ tube

■ Packaging technology

- UV printed 60µm PET EVOH PE film (100% virgin material).

- Extruded monolayer PE tube sleeve composed of 30% PIR (including PET), 20% PCR and 50% Green PE.

- Shoulder made of 100% Green PE.

- Cap made of 100% virgin PP.

■ More Decoplas™ tubes

Our other technologies :

Do you have a question?

Contact us now for more information!