With more than half a century of experience, Aisa continues to innovate in the tube packaging industry

x

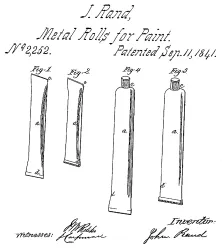

1841

Invention of tube packaging by John Goffe Rand, for artistic paint.

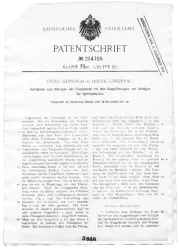

1925

Sprimag is established in Germany by Otto Heinrich, great-grandfather of Aisa’s current owners. Sprimag offers internal coating machines to enable the use of aluminium for tube packaging.

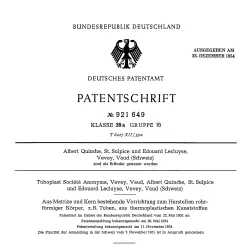

1951

Tuboplast in Vevey (Switzerland) invents a plastic tube composed of an extruded sleeve and an overmolded shoulder.

1966

Aisa begins to make machines to produce aluminium tubes.

1978

SAESA® (ABL)

First SAESA® laminate tube. Pre-moulded caps and shoulders are assembled with pre-printed laminate.

1983

PTH extruded tube

First compression moulding header for extruded tubes.

1989

PTH oval tube

First elliptically shaped compression moulded plastic tube.

1994

PET tube (TSM)

PET tubes mechanical stretched from a preform, decorated using SiOx barrier label.

1995

SAESA® (PBL)

First aluminium-free SAESA® laminate tube made using new heat sealing and hot air welding technologies on existing machines.

1996

DUAL chamber tube

Two completely sealed chambers in one tube made entirely from laminate film, featuring a compression moulded head.

2001

PET tube (PBM)

PET tube blown from a preform using a new pull-blow moulding process.

2004

Tube PTH Bacomex®

First high-barrier plastic tube made using multilayer compression moulding process on PTH 100.

2006

Tube PTH Synchroflow™

Compression moulded tubes combining any size shoulder diameters with very small orifices.

2006

SAESA® oval tube

First oval-shape laminate tube composed of pre-moulded shoulder, cap and aluminium barrier laminate.

2007

Decoseam™ Plastic laminate tube

First laminate tube without overlap side-seam weld. Laminate is edge-welded and a reinforcement tape applied.

2008

Bio-degradable PTH tube

100% biodegradable extruded tube produced with resins made from potato and corn starches.

2008

Decoseam™ paper laminate tube

Environmentally friendly tube made from laminate containing over 50% renewable resources (paper pulp).

2009

Think Green tube

Decoseam™ tube made with asymmetric adhesive laminated, “pouch like” laminate. Super-thin (178µm) and high performant (57N tensile test).

2011

Think Soft tube

Decoseam™ laminate tube with a soft-touch OPP surface. Digitally printed and UV adhesive-laminated with a metallised PET/PE base.

2011

SAESA® oval PBL tube

Introducing Aisa’s first oval shape, hot air shoulder welding system for PBL laminates.

2012

Decoseam™ Nano tube

Continues side seam welding process using extruded beads to weld the two laminate edges together and protect the aluminium film edges from the filled product. For sleeve diameters from 10 mm to 30 mm and highly efficient (57 N tensile test).

2013

SAESA® hair dye tube

Aluminium barrier laminate tube with Bacomex™ barrier shoulder validated for hair dye.

2015

Texsual tube

Decoseam™ tube made from a laminate featuring a digitally printed textile surface.

2015

DECOLAP tube

360° decoration in an overlap welded laminate tube. Achieved by combining active web trimming with a reduced overlap.

2015

Glasslike tube

Decoseam™ tube made of highly transparent laminate using mostly PP and Nylon.

2015

SAESA®600 tube

For 9 years our SAESA®500Line had been the world’s fastest tube maker. Now, as well as extending the diameter range to 16 mm, Aisa also increased the top speed to 600 tubes/minute.

2016

Decoseam™ NANO – simply a perfect seam

A laminate tube mimicking the look and dead-fold characteristics of an aluminium tube.

2016

Decoseam™ – the label is the package

Label-look tube using a high-shine, metallised PET surface, printed like a label.

2017

Decoplas™ the best of two worlds!

Combines luxurious touch and feel with reference decoration. Standard plastic tube extrusion with innovative labelling decoration.

2018

SHINE tube

Digital hybrid decoration combines inkjet, flexography UV, cold foil and silk screen printing efficiently in-line.

2019

ZERO DEFECT tube

Recycling-ready tube made of 100% PP mono-material.

2020

Decoseam™ PP tube

Tube certified recyclable at 99%.

2021

Decoplas™ tube

One hundred percent PE recyclable tube composed of 85% industrial waste from film production.

2021

Decoseam™ paper tube

Paper laminate tube embossed with foil embellishment.