The label is the package

■ What is it?

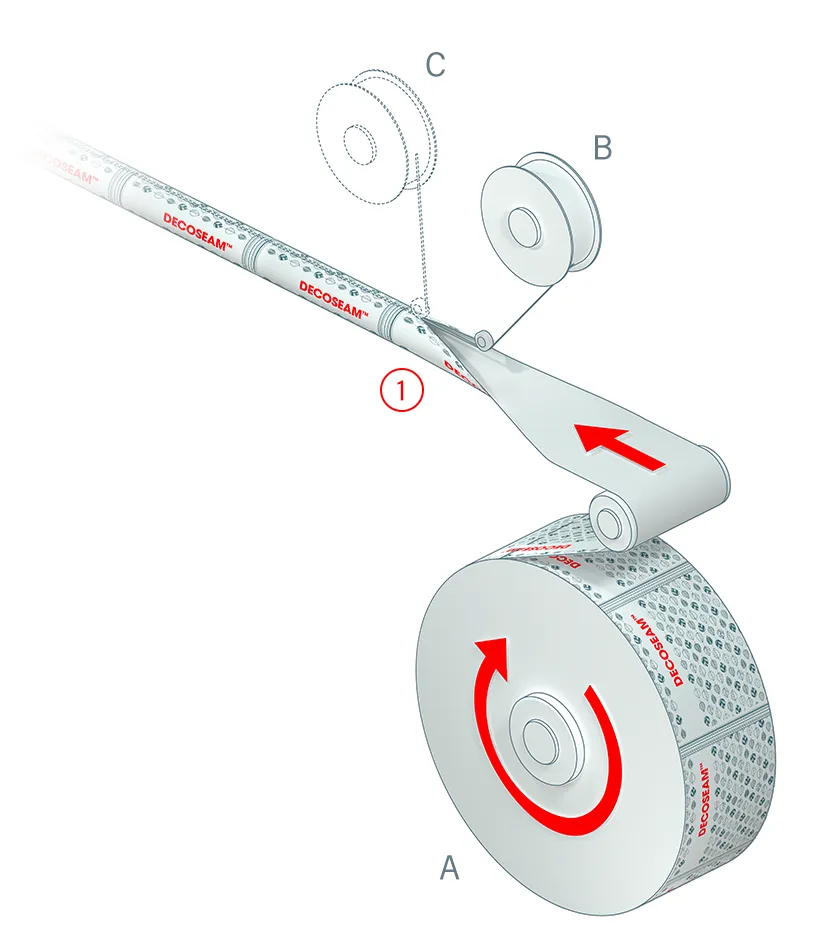

Decoseam™ is Aisa’s unique side-seam welding technology. For the first time, this technology allows the properties of the outer web layer to be changed independently from the inner web layer. In fact, because the outer layer is no longer welded onto the inner layer (overlap), we can now optimise for sustainability, security, touch, decoration or any other value-added functionality that customers desire.

1. Decoseam™ strip is fed into the centre of the butt-weld seam, while the flat decorated laminate is formed into an endless tube!

A. Decorated laminate

B. Internal strip

C. External strip

Tube cut side-seam area

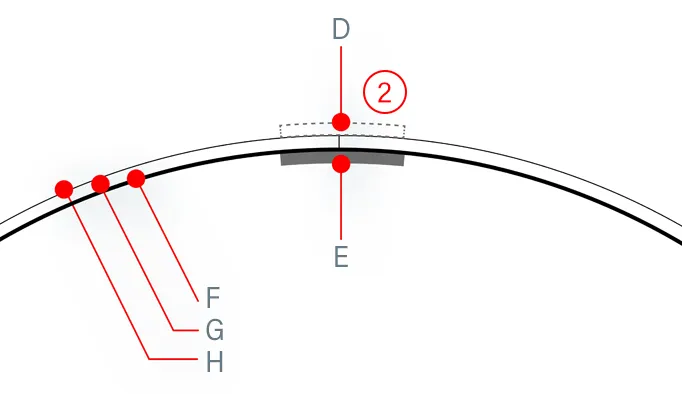

2. To prevent the paperboard from absorbing external moisture, a second strip is welded on the outside of the sleeve.

D. External strip

E. Internal strip

F. Barrier layer

G. Plastic or paperboard laminate

H. Decoration layer

■ Available on

SAESA®100, SAESA®200, BM 120 and BM 240 lines running at outputs of 100, 200, 120 and 240 tubes or sleeves/min.

■ New market opportunities

- Allows the use of new functional web structures.

- Tube performance guaranteed.

- Use of DIBS welding system to edge-weld the tube side-seam with a reinforcement strip.

- 360° decoration gives greater print surface and eliminates design gap.

- Improved haptics due to freedom of the top layer.

- Tube diameter range from 19 mm to 63.5 mm.

Body

■ Packaging technology

- Digitally CMYK inkjet-printed, creating effects using the metallic surface of the substrate.

- Laminate sleeve high-gloss structure; 300 µm thick, metallised PET surface and 9 µm aluminium barrier layer.

- Edge-welded, fully decorated side-seams with reinforcement strip PE/PET/PE on the inside.

- Aluminium layer for product protection. Thin inner PE layer for reduced scalping.

- Heading using pre-moulded PE shoulder, high-frequency welded to the tube sleeve.

- Cylindrical screw cap.

- Identical barrier properties as standard ABL tube (BIF 1).

- Bounce back index: 31%.

Nature Sourced

■ Packaging technology

- Digitally CMYK inkjet-printed.

- ~ Eighty percent bio-sourced tube made of laminate PEbio70/PAP150g/PETHB12/PEbio70.

- Bio-sourced PE shoulder.

- Paper contributes to the unique touch.

- PET HB adds mechanical strength and barrier properties.

- Identical barrier properties as standard PBL tube (BIF 1).

- Bounce back index: 78%.

TEXsual

■ Packaging technology

- Digitally CMYK inkjet-printed.

- PBL 300 µm textile-based laminate.

- PE/PE EVOH PE/PE + textile laminate structure.

- Tube heading by PTH compression moulding technology.

- Identical barrier properties as standard PBL tube (BIF 1).

- Bounce back index: 74%.

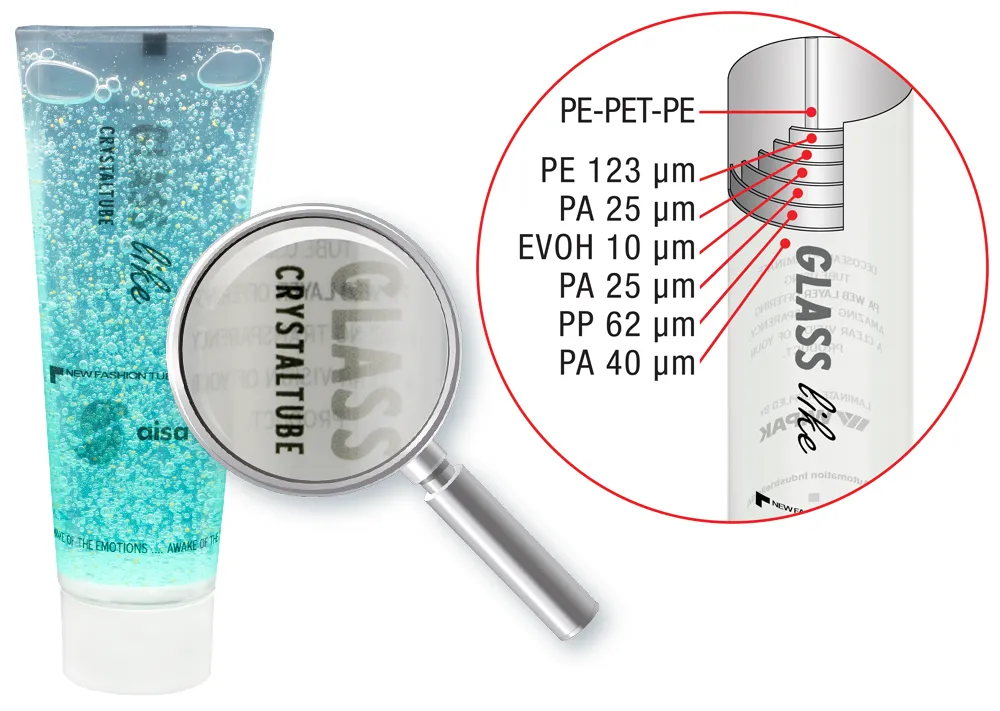

GLASS like

■ Packaging technology

- Digitally CMYK inkjet-printed.

- PA/PP/PA/PE laminate structure.

- Heading using pre-moulded PE shoulder, hot air welded to the tube sleeve.

- Improved barrier properties vs standard PBL tube (BIF 1.2).

- Heading using pre-moulded PE shoulder, heat-sealed to the tube sleeve.

- Bounce back index: 82%.

■ More Decoseam™ tubes

Our other technologies :

Do you have a question?

Contact us now for more information!