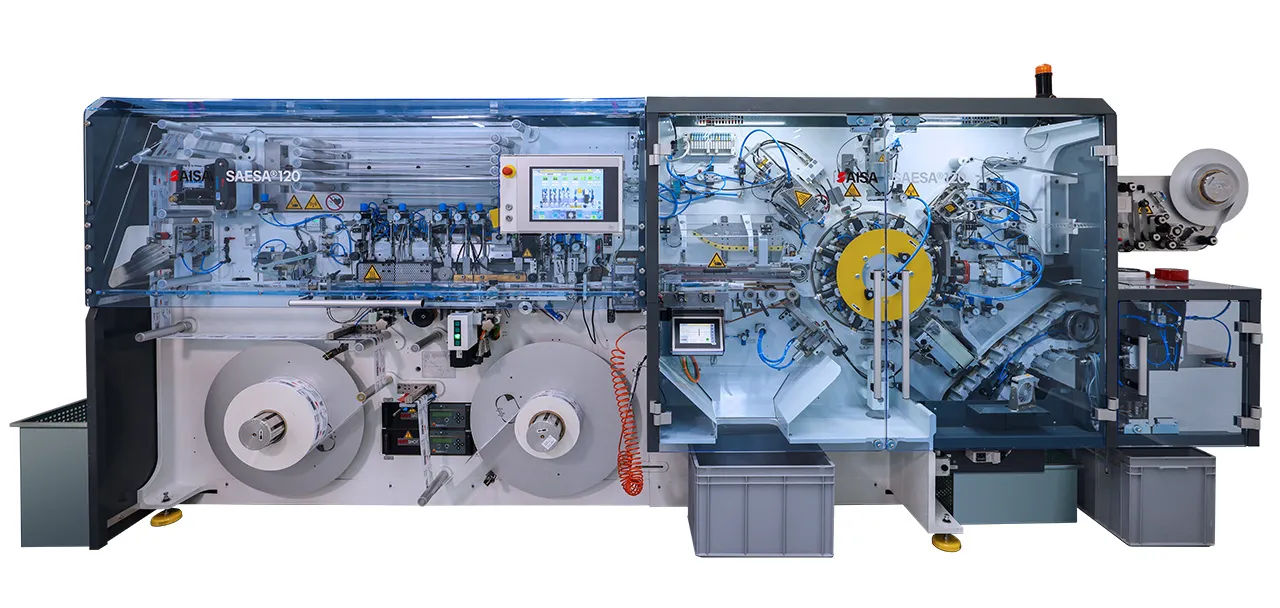

Fully automatic machine equipped with the latest overlap welding technology, dedicated to the production of ABL and PBL laminate tubes at speeds of up to 120 tubes per minute.

Hotline : +41 840 84 84 84

■ Key benefits

- Smallest footprint for an output of 120 tubes/min. on the market

- Only machine with continuous in-line welding quality control on the market

- Simple and very efficient transfer and tooling

- Quick change-over

- Easy to operate

The SAESA®120 is the fastest single-mandrel machine with minimum tooling on the market. Particularly suited for the oral care and pharmaceutical sectors, it can produce up to 40 million tubes per year.

The SAESA®120 is now equipped with our newest body maker welding system – DBHS. This system offers two main advantages:

- The PBL-only version does not require HF-High Frequency welding system

- With the ABL option installed, the machine switches from ABL to PBL using the same body maker tooling.

Technologies :

(Click on the icon for more information)

Machine specifications

Machine capabilities

Up to 120 tubes/min.

Tube Ø19 mm* to 40 mm

Side-seam up to 24m/min.

* Smaller diameter possible upon request.

Welding technologies

DBHS – Double Belt Heat Sealing (ABL and PBL or PBL only)

Value-adding options

AFQS – Automatic Functional Quality System

Safety seal applicator

Snap-on cap applicator

Packing conveyor integration

Production Data Interface to MES

Quality Control Systems

iQ-Seam Compression