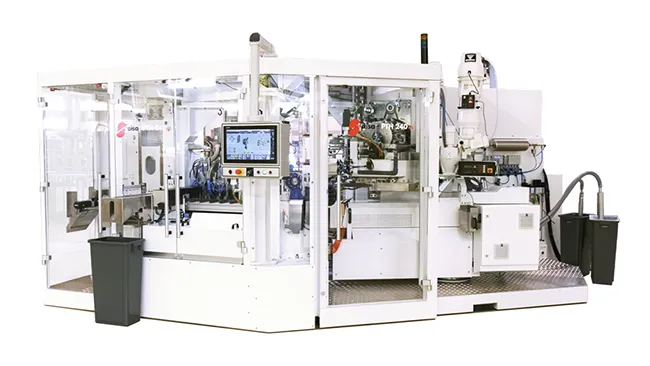

Our latest development in the PTH range, the PTH 240 provides heading of tubes at speeds of up to 240 pieces per minute, using Aisa’s well-proven Synchroflow™ compression moulding technology.

■ Key benefits

- High performance production machine

- 240 tubes/minute produced with only 24 tools

- Flexible line integration solution to suite different line configurations

- Low maintenance

- Link to Aisa CM 240 capping machine through direct or indirect transfer

- High flexibility to meet countless tube design needs, for today and tomorrow

The PTH 240 header is based on Aisa’s world-famous PTH concept; a state-of-the-art, fully automatic machine tube heading machine – forming a shoulder and simultaneously bonding it to the tube body.

This machine features our well-proven Synchroflow™ , 2-step compression moulding technology, as well as the performance gains delivered by high-cooling tooling.

High-cooling tooling

- Reduced tooling weight.

- Optimised cooling circuit for better heat exchange.

- Up to 20% higher productivity.

Technologies :

(Click on the icon for more information)

Machine specifications

Machine capabilities

Up to 240 tubes/min.

Tube Ø13.5 mm to 63.5 mm

Tube length 50 mm to 230 mm

Value-adding options

Printed sleeve orientation

Oval tube heading system

Vaccum-assisted, positive tube transfers, both upstream and downstream

Accumulators for line integration

Quality Control Systems

Shoulder thickness measurement

Shoulder and orifice quality control

Sleeve orientation inspection