The latest generation of sleeve-making equipment, combining the extrusion and labelling labelling processes together, to deliver the benefits of both worlds, for a tube with outstanding decoration capabilities.

Hotline : +41 840 84 84 84

■ Key benefits

- Photo graphics on 100% of the tube surface, without any “no-print” zone

- Seamless look – entire tube fully covered by printing

- True shiny metallic and holographic effects capability

- Barrier properties to mitigate oxygen and flavour transmission

- Tube with strong memory effect, always bounces back after squeezing

- Save cost by printing film instead of complex web structure

- Change sleeve artwork in “no time”

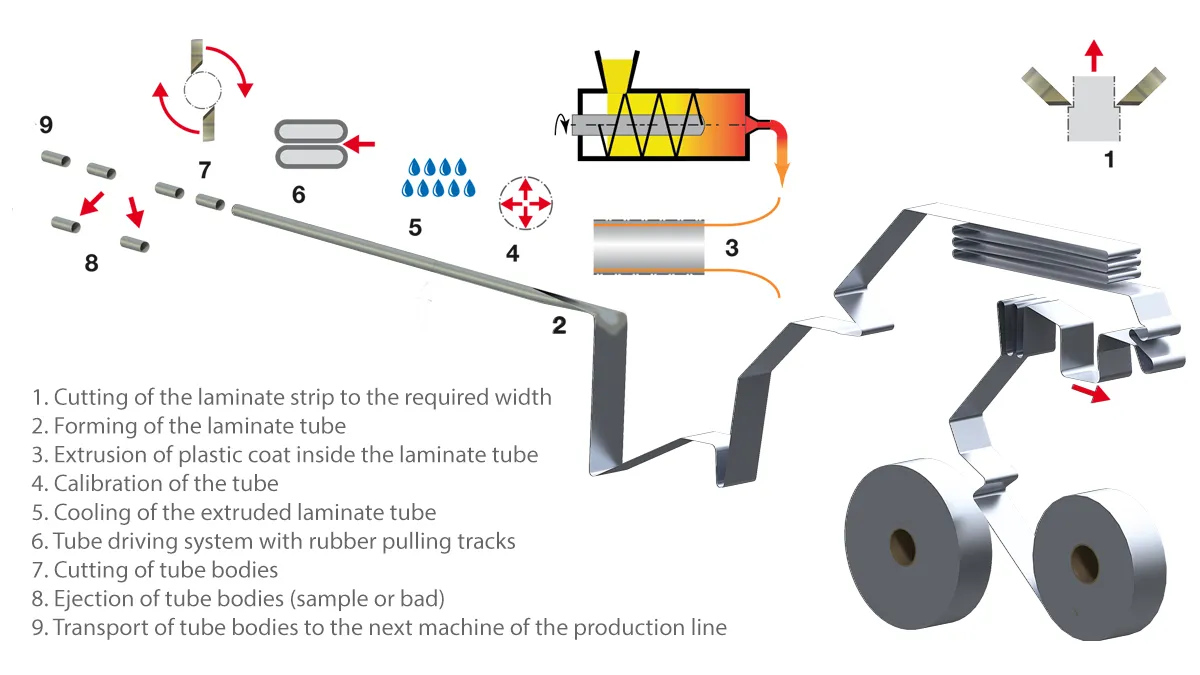

The DXL 120 machine produces Decoplas™ sleeves from extruded plastic and printed film material. The sleeves are then transferred by the exit conveyor to a downstream machine, usually a PTH header.

This machine has been designed for maximum flexibility, allowing a large range of body diameters to be produced.

The DXL 120 comprises 3 modules: a film unwind, an extruder, and a pulling/cutting section.

DXL 120 Process

Machine specifications

Machine capabilities

Up to 120 sleeves/min.

Sleeve Ø25 mm to 63.5 mm

Extruder linear speed up to 24m/min.

Value-adding options

Thickness and diameter control for sleeves